China supplier carbide button used for oil exploration

The application of the carbide button bits

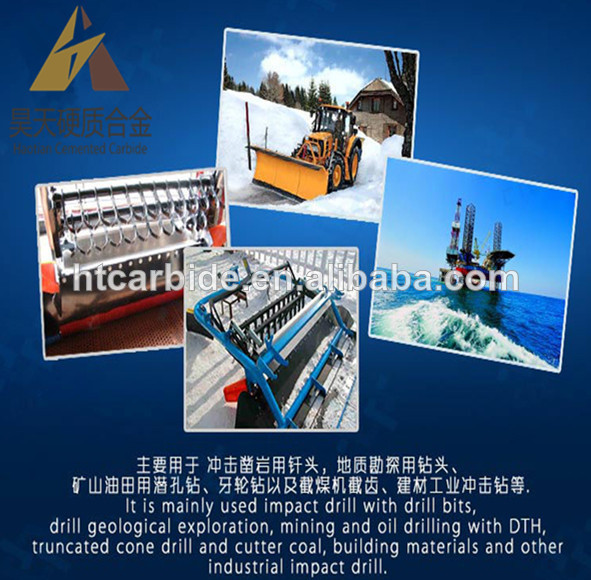

1)Tungsten carbide button is widely used in petroleum drilling, snow plow equipment, cutting tools ,mining machinery, road maintenance and coal drilling tools.

2)It is also can used asexcavating tools for Tunneling,quarrying,mining and Construction.In addition, as drill Accessories for rock drilling machine and deep hole drilling tools .

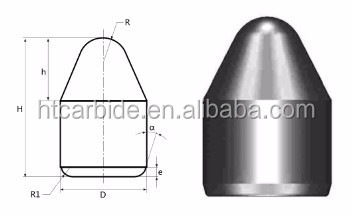

1.Products display

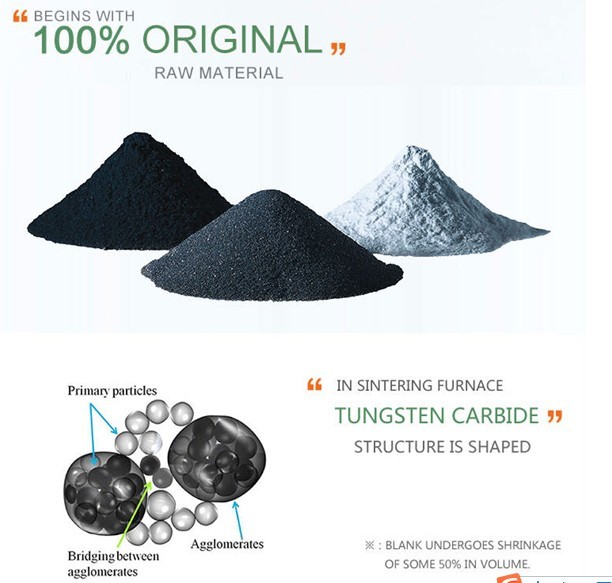

2. Advantages

1. Material: 100% virgin raw material. Various grades for choice.

2. With strict quality control system

3. Excellent properties, stable quality, high processing precision, good wear resistance and impact resistance.

4. OEM & ODM;

5. Customized order is welcomed and accepted.

6. Free Sample is available for your quality test.

3.Cemented carbide main grade for oil filed and mining

Grade | Density g/cm3 | T.R.S M Pa | Hardness HRA | Performance & Application recommended |

HG6 | 14.75~14.95 | ≥2600 | 90.0-90.8 | Applicable to the geological exploration, coal mining, electric wire. Suitable for hard sandstone, limestone, and alternate hard and soft rock. |

HG8C | 14.60-14.80 | ≥2400 | 87.0-89.0 | Applicable to the percussive rotary drilling machine drill bit, drilling in hard and solid rock. |

HG9C | 14.5-14.65 | ≥2500 | 87.5-88.5 | For brazing sheet, percussive rotary ball and mine roller drill tooth, cutting into the soft rock and hard rock |

HG10C | 14.35-14.55 | ≥2750 | 87.0-88.0 | For brazing sheet, percussive rotary ball and mine roller drill tooth, cutting into the soft rock and hard rock |

HG11C | 14.30-14.50 | ≥2750 | 86.5-88.0 | Applies to inlay heavy rock drills, percussive-Rotary drilling machine drill |

HG13 | 14.10-14.30 | ≥2800 | 86.0-87.5 | Applicable to the manufacture of oil Cone Drill, drilling in hard rock, medium hard rock, also applies to the percussive-Rotary drilling machines and heavy rock drill bit |

HG15 | 14.00-14.20 | ≥2800 | 85.5-87.0 | Applicable to the manufacture of cone bits, chisel into various types of rock |

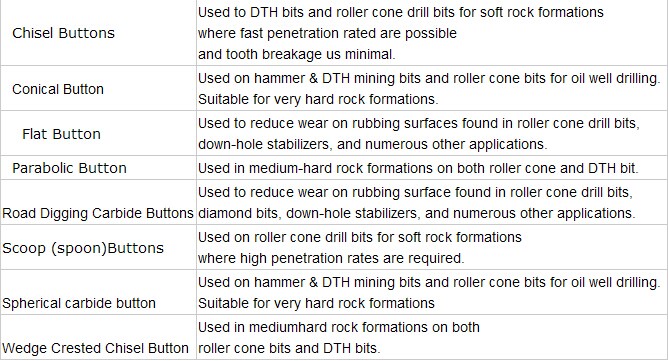

4. Haotian carbide buttons-----Application recommend

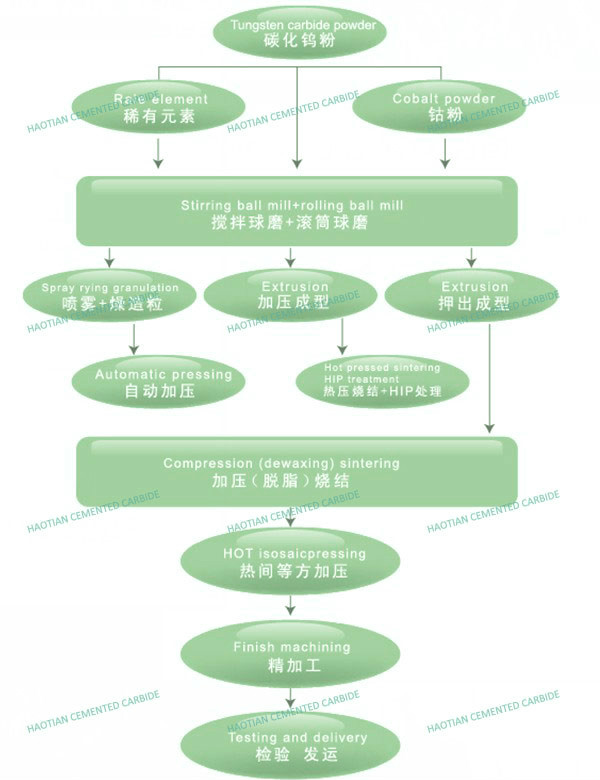

5. Production process

6. Advanced production equipment

1. Sintering Furnace

Our 6MPa sintering furnace is imported form Germany, which can produce 12,000 kg carbide products ...

2. Auto pressing machine

Our auto Pressing Machine can press more than 400 carbide products one hour one machine.

7. Strict Quality Control System

8. Used for the mining fileds:

8. Payment

For samples, our payment is 100% deposit by T/T.

For bulk order, our payment is 30% deposit by T/T, 70% balance by T/T before shipping.

Or you can choose 100% L/C at sight.

9. Packing

1. Standard Packing: plastic box inside, carton or wooden box outside;

2. we also pack according to customers' requirement .

10. Shipping

We use the main delivery companies as below:

For stock items, we’ll arrange the shipment within 2-3 days after payment received.

For customized items, the delivery time is about 20-30 working days.

Estimate delivery time for different courier:

- DHL: 10-14 working days

- FedEx: 7 to 10 working days

- UPS: 7 to 10 working days

- EMS: 10-14 working days

Delay is possible and depends on your local custom & postal services. Sometimes custom will hold the order for random check, you also contact your local postal services to see if there is any international incoming mail.

11. After-sale service

Welcome your inquiry at any time!

Dear customer, in order to improve our efficiency of communication,

Please inform us the following information while you sending inquiries:

1:Specific size or drawings,

2:Operation environment.

3:Purchase quantity for each item.

4:Special requirements.

5:Grade.